Testing Laboratory

Feather Industries has an on-site lab where various testing takes places to ensure quality standards are met. We test every product we purchase, process and sell. A database is maintained referring every test to a specific lot. This ensures the consistency of the quality and that we meet or exceed all Canadian and International standards.

Representative samples of every lot purchased, processed or sold are kept for a minimum of five years.

- Fat & Oil Content

- Oxygen Count/turbidity

- Filling Power

- Sample Shorting

- Preparing Samples

- Content Analysis

- Species Determination

To test for fat and oil content a sample of distilled water, pretreated with the down being tested is added to a Pyrex beaker and mixed with Ether. This mixture is heated and through a series of regeneration processes, the fat and oil is extracted and weighed.

Industry standards are set at a range between 1.5 percent and 3.0 percent. Feather Industries falls within that range.

Industry standards are set as 20, however, Feather Industries consistently exceeds these minimum standards. In fact, any products that are above 10 we do not consider processed.

In conjunction with the oxygen test, the same sample of filtered water is poured into a thousand millimeter Pyrex tube. Small amounts of filtered water are released until an indicating mark at the base of the tube can clearly be seen indicating the amount of suspended particles in the beaker. The clearer the water, lower the level of the turbidity and cleaner the products.

Industry standards are set at 300mm, however, Feather Industries will not ever release a product below 600mm and consistently measures to 1000mm and higher.

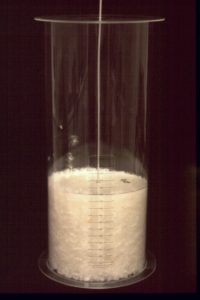

To determine the Filling Power, a one ounce representative sample is placed in a Plexiglas cylinder. The sample is then conditioned for 72 hours in a controlled environment. A “paddle” is slowly released into the cylinder and compresses the sample until the “paddle” stops. At that point the level is measured which indicates the ability of the sample to trap air. This step is repeated twice more and the average of the three levels is calculated to determine the volume per cubic inch of filling power. Generally speaking the greater the Loft number is, the higher the quality of down.

The function of the machine is to quickly estimate down content by weight vs. feather content by weight. For precise measurement hand separation is required.

For a product to be labeled as Goose a certain percentage of Goose Down clusters or feather must be present, and internationally this percentage varies. In Canada and the United States the minimum percentage is 90%.